This objective is one of the major challenges facing our world: Energy supply and consumption

should be more climate-friendly. Sustainability and environmental compatibility play an important

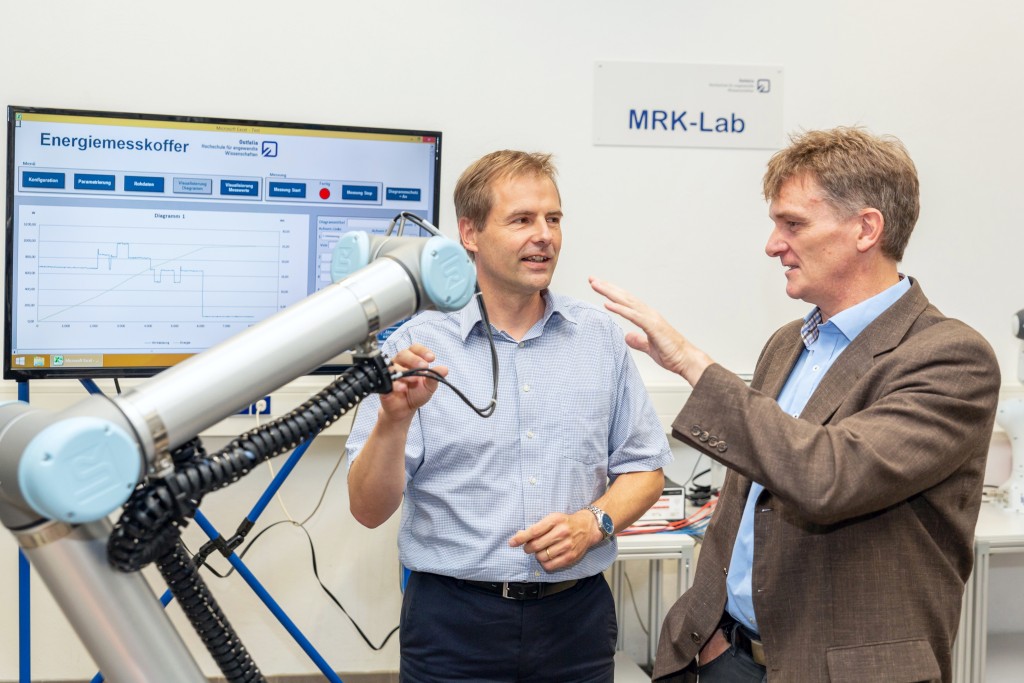

role in the research area Renewable Energies and Resource Efficiency at Ostfalia. In this

interview, the Professors Holger Brüggemann and Lars Kühl talk about the projects they are working

on and who benefits from them. And they explain why the research area enriches their work.

Professor Brüggemann, Professor Kühl, how much energy can companies save in production?

Holger Brüggemann: In our projects we have found that companies can reduce their consumption by

up to 30 percent. In Lower Saxony the areas of industry, trade, commerce and services account for

more than 40 percent of the total energy consumption. This shows how great the potential is that we

have not exploited yet.

Why is it important that we use energy more economically?

Holger Brüggemann: We have set ourselves high climate protection goals. The master plan for the

greater Brunswick area provides that we want to reduce energy consumption by half until the year

2050 and greenhouse gas emissions by 95 percent. There are similar plans for Lower Saxony and

Germany-wide. In order to achieve these goals, there are basically only two ways. First, we need

more renewable energy sources. And secondly, we have to increase energy efficiency significantly –

and that is precisely what I work on in the production environment.

Lars Kühl: I am working on the use of renewable energies in buildings – the supply of heating,

cooling and electricity. Geothermal and solar thermal systems, heat pumps and photovoltaics: these

are just a few of the headings for the large range of topics that we cover with our research

projects. And we also include these topics in teaching: we pass the findings from our projects on

to the students. Again and again, lectures take place on site in businesses and buildings. With

ongoing processes, students can follow optimisation measures – so to speak live and in colour. This

close proximity of research and teaching also makes our projects so exciting.

Why don’t more companies concern themselves with renewable energies and energy efficiency?

Holger Brüggemann: Many underestimate the opportunities to save energy. They know that

compressed air tools are not particularly efficient and leaks are a waste of resources. But they

are surprised to hear that exchanging a pneumatic screwdriver for an electric screwdriver uses 90

percent less energy. Many small and medium-sized companies are also working to capacity already.

They often lack the time to address this subject.

And this is where you come in?

Lars Kühl: Yes, it is also up to us to inform them about the potential savings and how to use

them. We visit plants, offices and residential buildings, equip them with measurement technology

and record the consumption of electricity, heat and cold. Then we explain how renewable energies

and efficiency measures can improve the energy consumption figures. We also develop concepts for

the energy supply of entire buildings. The new construction of the Oeding printing plant in

Brunswick is an energy-plus building generating its own energy. Ostfalia made a significant

contribution to the planning of the building.

What else have you worked on?

Holger Brüggemann: The expansion of the Lower Saxony “learning factory” for resource efficiency

at Ostfalia (NiFaR). This project gave rise to a non-profit organisation many partners are actively

involved in and many employees from companies have been trained in. In this way we have shown many

companies new ways and means to improve energy efficiency. In the field of robotics, we have worked

with Volkswagen AG to determine which influences affect energy consumption. If you change the robot’

s programming, you can save up to 40 percent of the energy.

Who is involved in your research area?

Lars Kühl: Our research area involves first and foremost the Ostfalia Faculties of Mechanical

Engineering, Supply Engineering as well as Automotive Engineering and Electrical Engineering. The

reason is that electromobility is an important issue: We can integrate storage capacities from

vehicles into the energy supply of buildings. We are also well networked outside of Ostfalia: via

the contact with other universities, industrial enterprises, planning offices as well as

residential property developers and municipalities we can integrate issues such as building

construction and architecture, control and measurement engineering. Thus we work according to the

state of the art in real projects and are oriented towards the needs of the users.

Holger Brüggemann: It helps us that the topics digitisation and Industry 4.0 play a major role

in businesses. Whoever digitalises production also quickly sees substantial progress after only a

short time. Our research area benefits from the fact that Ostfalia has positioned itself quite

strongly in digitisation.

Lars Kühl: It is important that there is an interface to the social scientists. This way we

examine how the optimisation measures and the use of modern technologies can gain the necessary

acceptance by the users.

Why does the research area enrich your work?

Holger Brüggemann: Because I can contribute to ensuring that we achieve our climate protection

goals. And because investments in the energy efficiency of machines and plants generally lead to

increased productivity. By means of declining energy consumption we can also improve the

competitiveness of companies. In my view, this is a very sensible task …

Lars Kühl: …especially since we do not just implement the energy-saving measures. But also

convey the numerous possibilities offered by renewable energy and energy efficiency to our students

in teaching. Like this, we ensure that our research has a sustainable impact.