EFRE

project: Lightweight and graded plastic material structures in industry 4.0 " Legra".

ERDF project: Lightweight and graduated material structures made of plastic in industry 4.0

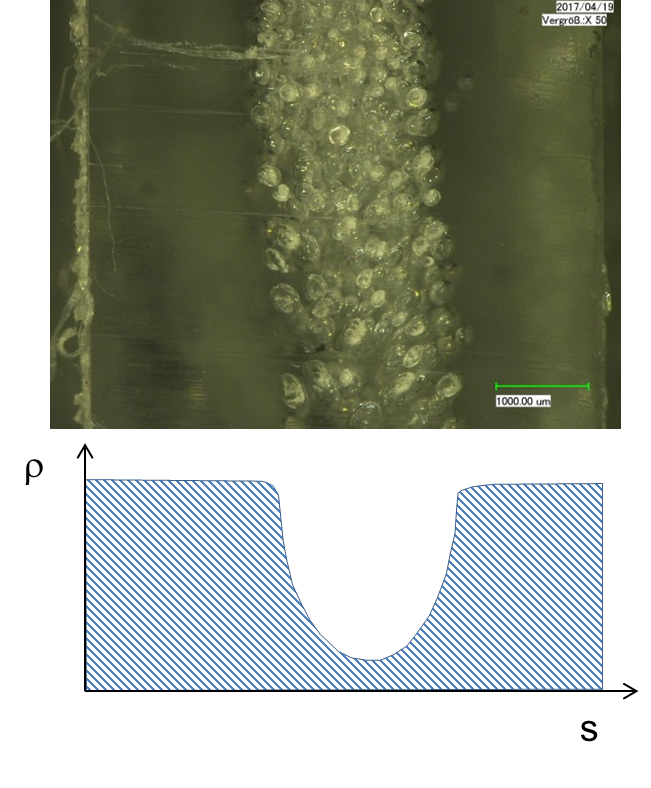

"Legra" Within the framework of the ERDF project: Lightweight and graduated material structures

made of plastic in industry 4.0 "Legra", work is being carried out with inexpensive standard

plastics. These thermoplastics such as polypropylene (PP), acrylic butadiene styrene copolymer

(ABS) or polycarbonate (PC) are processed in a mass production process of injection molding. In

order to be able to specifically adjust the properties of a thermoplastic component in injection

molding and to be able to produce very light structures and components, research results in process

engineering and tooling technology are used here and further developed in line with applications.

Another aspect that should not be underestimated in the context of this project is that lightweight

materials should be more than just light. They will be tailored to their respective application and

provided with additional functions. Well-known examples are the insertion of structures or lines to

be conductively coated into injection molded parts in order to produce injection molded

interconnect devices. It is also conceivable that in the sense of a graded material, e.g. in a

component wall, the coefficient of thermal expansion of the material varies by varying the material

composition. The material then shows a different thermal expansion on one side than on the other

side. The setting of a defined electrical conductivity of a non-conductive plastic also reduces the

electrical chargeability. It enables the non-conductive plastic to be used in organic electronics

or optoelectronics.

ERDF project: Lightweight and graduated material structures made of plastic in industry 4.0

"Legra" Within the framework of the ERDF project: Lightweight and graduated material structures

made of plastic in industry 4.0 "Legra", work is being carried out with inexpensive standard

plastics. These thermoplastics such as polypropylene (PP), acrylic butadiene styrene copolymer

(ABS) or polycarbonate (PC) are processed in a mass production process of injection molding. In

order to be able to specifically adjust the properties of a thermoplastic component in injection

molding and to be able to produce very light structures and components, research results in process

engineering and tooling technology are used here and further developed in line with applications.

Another aspect that should not be underestimated in the context of this project is that lightweight

materials should be more than just light. They will be tailored to their respective application and

provided with additional functions. Well-known examples are the insertion of structures or lines to

be conductively coated into injection molded parts in order to produce injection molded

interconnect devices. It is also conceivable that in the sense of a graded material, e.g. in a

component wall, the coefficient of thermal expansion of the material varies by varying the material

composition. The material then shows a different thermal expansion on one side than on the other

side. The setting of a defined electrical conductivity of a non-conductive plastic also reduces the

electrical chargeability. It enables the non-conductive plastic to be used in organic electronics

or optoelectronics.

ERDF project: Lightweight and graduated material structures made of plastic in industry 4.0

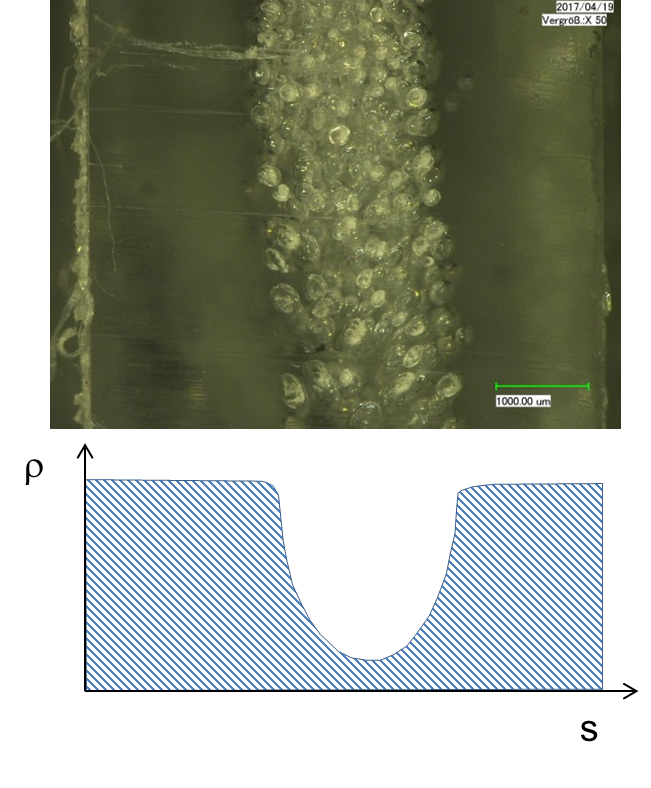

"Legra" Within the framework of the ERDF project: Lightweight and graduated material structures

made of plastic in industry 4.0 "Legra", work is being carried out with inexpensive standard

plastics. These thermoplastics such as polypropylene (PP), acrylic butadiene styrene copolymer

(ABS) or polycarbonate (PC) are processed in a mass production process of injection molding. In

order to be able to specifically adjust the properties of a thermoplastic component in injection

molding and to be able to produce very light structures and components, research results in process

engineering and tooling technology are used here and further developed in line with applications.

Another aspect that should not be underestimated in the context of this project is that lightweight

materials should be more than just light. They will be tailored to their respective application and

provided with additional functions. Well-known examples are the insertion of structures or lines to

be conductively coated into injection molded parts in order to produce injection molded

interconnect devices. It is also conceivable that in the sense of a graded material, e.g. in a

component wall, the coefficient of thermal expansion of the material varies by varying the material

composition. The material then shows a different thermal expansion on one side than on the other

side. The setting of a defined electrical conductivity of a non-conductive plastic also reduces the

electrical chargeability. It enables the non-conductive plastic to be used in organic electronics

or optoelectronics.